The Beginning

In 1961-1967, an OECD Group of Experts in Cold Forging promoted and established international contacts and co-operations in the field of cold forging. The group consisted of Dr. H. Ll. David Pugh, Scotland, Prof. Dr. Otto Kienzle, Germany, Prof. Dr. Olof Svahn, Sweden, and other distinguished members of the Institution for Production Engineering Research (CIRP). Supported by the Organization for Economic Cooperation and Development (OECD), the Group of Experts established an international cooperative research program and prepared a survey of literature on cold forging and a dictionary. At the same time national cold forging groups had been formed in Belgium, Western Germany, the Netherlands and Sweden in addition to the already existing group. As the financial support by OECD ended, the Group decided to be able to stand on its own two feet and founded the International Cold Forging Group (ICFG) on 15 November 1967.

Table of Plenary Meetings and chairmen during the past 30 years

2016

Venue: Stuttgart, GER

Chairman: Mr. M. Yamanaka

Vice-chairman: Dr. M. Hänsel

2015

Venue: Daejeon, KOR

Chairman: Dr. M. Hänsel

Vice-chairman: Mr. M. Yamanaka

2014

Venue: Ankara, TR

Chairman: Dr. M. Hänsel

Vice-chairman: Mr. M. Yamanaka

2013

Venue: Paris, F

Chairman: Dr. M. Hänsel

Vice-chairman: Prof. A.E. Tekkaya

2012

Venue: Soenderborg, DK

Chairman: Dr. M. Hänsel

Vice-chairman: Prof. A.E. Tekkaya

2011

Venue: Soenderborg, DK

Chairman: Prof. A.E. Tekkaya

Vice-chairman: Dr. M. Hänsel

2010

Venue: Darmstadt, GER

Chairman: Prof. A.E. Tekkaya

Vice-chairman: Dr. M. Hänsel

2009

Venue: Shanghai, CN

Chairman: Prof. A.E. Tekkaya

Vice-chairman: Prof. K. Kuzman

2008

Venue: Warsaw, Pl

Chairman: Prof. A.E. Tekkaya

Vice-chairman: Prof. K. Kuzman

2007

Venue: Padova, I

Chairman: Prof. K. Kuzman

Vice-chairman: Prof. A.E. Tekkaya

2006

Venue: Changwon, ROK

Chairman: Prof. K. Kuzman

Vice-chairman: Prof. A.E. Tekkaya

2005

Venue: Chester, UK

Chairman: Prof. K. Kuzman

Vice-chairman: Dr. J. Groenbaek

2004

Venue: Istanbul, TR

Chairman: Prof. K. Kuzman

Vice-chairman: Dr. J. Groenbaek

2003

Venue: Columbus (Ohio), USA

Chairman: Dr. J. Groenbaek

Vice-chairman: Prof. K. Kuzman

2002

Venue: Helsinki, SF

Chairman: Dr. J. Groenbaek

Vice-chairman: Prof. K. Kuzman

2001

Venue: Tsukuba, JPN

Chairman: Dr. J. Groenbaek

Vice-chairman: Prof. K. Kuzman

2000

Venue: Nuremberg, GER

Chairman: Dr. J. Groenbaek

Vice-chairman: Dr. V. Maegaard

1999

Venue: Ljubljana, SLO

Chairman: Prof. M. Geiger

Vice-chairman: Prof. L. Cser

1998

Venue: Gothenburg, S

Chairman: Prof. M. Geiger

Vice-chairman: Prof. L. Cser

1997

Venue: S'Hertogenbosch, NL

Chairman: Prof. M. Geiger

Vice-chairman: Prof. L. Cser

1996

Venue: Györ, HUN

Chairman: Prof. M. Geiger

Vice-chairman: Prof. L. Cser

1995

Venue: Lyngby, DK

Chairman: Prof. N. Bay

Vice-chairman: Prof. R. Crafoord

1994

Venue: Padova, I

Chairman: Prof. N. Bay

Vice-chairman: Prof. R. Crafoord

1993

Venue: Osaka, JPN

Chairman: Prof. N. Bay

Vice-chairman: Prof. R. Crafoord

1992

Venue: Darmstadt, GER

Chairman: Prof. N. Bay

Vice-chairman: Prof. R. Crafoord

1991

Venue: Bath, UK

Chairman: Prof. R. Geiger

Vice-chairman: Ir. H.P. Pouw

1990

Venue: Imatra/Helsinki, SF

Chairman: Prof. R. Geiger

Vice-chairman: Ir. H.P. Pouw

1989

Venue: Erlangen, GER

Chairman: Prof. R. Geiger

Vice-chairman: Ir. H.P. Pouw

1988

Venue: Warsaw, PL

Chairman: Prof. R. Geiger

Vice-chairman: Ir. H.P. Pouw

1987

Venue: Warsaw, PL

Chairman: Prof. T. Wanheim

Vice-chairman: Dr. N. Bay

1986

Venue: Vaduz, FL

Chairman: Prof. T. Wanheim

Vice-chairman: Dr. N. Bay

1985

Venue: Gothenburg/Karlstad/Stockholm, S

Chairman: Prof. T. Wanheim

Vice-chairman: Dr. N. Bay

1984

Venue: Nagoya, JPN

Chairman: Prof. T. Wanheim

Vice-chairman: Dr. J. Gronbaek

1983

Venue: Tarbes, F

Chairman: Mr.T.M.B.Sessions

Vice-chairman: Dr. J. Gronbaek

1982

Venue: Lyngby/Nordborg, DK

Chairman: Mr.T.M.B.Sessions

Vice-chairman: Mr. K. Standford

1981

Venue: Birmingham, UK

Chairman: Mr.T.M.B.Sessions

Vice-chairman: Mr. R. Lawson

1980

Venue: Senlis, F

Chairman: Mr.T.M.B.Sessions

Vice-chairman: Mr. R. Lawson

1979

Venue: Stuttgart, GER

Chairman: Ir. P.I.M. Boes

Vice-chairman: Mr. R. Lawson

1978

Venue: Sunderland, UK

Chairman: Prof. K. Lange

Vice-chairman: Mr. R. Lawson

1977

Venue: Liege/Herstal, B

Chairman: Prof. K. Lange

Vice-chairman: Mr.T.M.B.Sessions

1976

Venue: Paris/Senlis, F

Chairman: Prof. K. Lange

Vice-chairman: Mr.T.M.B.Sessions

1975

Venue: Apeldoorn, NL

Chairman: Prof. K. Lange

Vice-chairman: Mr.T.M.B.Sessions

1974

Venue: Gothenburg, S

Chairman: Prof. K. Lange

Vice-chairman: Mr.T.M.B.Sessions

1973

Venue: Brno, CS

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

1972

Venue: Stuttgart, GER

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

1971

Venue: East Kilbride, UK

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

1970

Venue: Paris, F

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

1969

Venue: Paris, F

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

1968

Venue: London, UK

Chairman: Dr. H.Ll.D. Pugh

Vice-chairman: Mr.T.M.B.Sessions

Introduction to Cold Forging

Cold forging is a common industrial process in which metal workpieces are plastically shaped by suitably contoured dies to form a final desired shape. The process itself is a predominantly compressive one in which the workpiece is squeezed between the dies.

Cold forging is an important process being used in many industries, for example the automotive industry in which a huge annual tonnage of cold forged components are used.

Important aspects in cold forging are: the die material and shape, the lubricant, the workpiece material, and the temperature.

Cold forging is generally understood to mean forging at room temperature or a temperature at which no microstructural changes occur as a result of the process. Warm forging is now gaining in popularity because ambient temperatures are elevated a little to decrease the required loads whilst maintaining good tolerances for the products.

Numerical analyses and simulations are now used commonly in the cold forging industry to optimize the processes and to decrease overall costs. For example in multi-step processes the number and nature of each step are very important in the cost of the finished component.

It is the objective of the ICFG to further the use of cold forging, therefore the organization is concerned with all the above variables as well as numerical analyses and simulations.

General Information

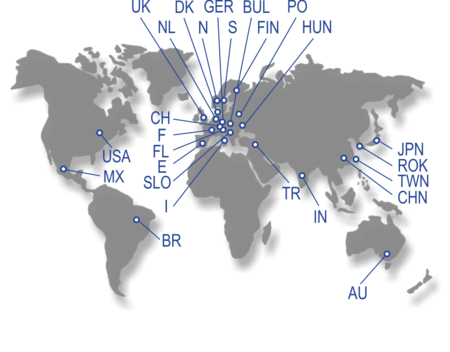

The ICFG is represented worldwide by members from industry and academia.

Objectives of ICFG

According to the preamble of the ICFG constitution, the objective of the group is to promulgate the economic advancement of cold forging

– by encouraging and co-ordinating national and international co-operation,

– by stimulating research,

– by disseminating knowledge of relevant processes and sciences.

Therefore the major part of activity concentrates on subgroup work with the aim of preparing and presenting information to the public, e.g. data sheets and guidelines.

Structure of ICFG

The ICFG consists of subgroups, each active in a particular sub-division of the main fields of interest. Each subgroup is responsible for its own program and administration, including the election of its officers. As the number of permanent members is restricted in order to maintain close personal contacts and to cut down administrative work, the subgroups are authorized to invite any person to collaborate temporarily. This regulation providing a high degree of flexibility to the subgroups has proved to be very effective. Chairman and Vice-Chairman are elected for a two year period of office and are eligible for a second term of two years. The main group consists of permanent members and assemblies annually at the Plenary Meeting to review progress, receive reports and initiate, modify or terminate subgroups activities. Of very great importance is the link between ICFG and CIRP by the double-membership of leading experts in both international institutions.